Changzhou Huazhan Machine Manufacture Co., Ltd.

Experts of Building Materials Machinery

- Contact us now

- leonhua@czhuazhan.cn

Experts of Building Materials Machinery

Quick Details

Place of Origin: Jiangsu, China (Mainland) Brand Name: Huazhan Model Number: ACM202

Shaping Mode: Preform Mould Product Material: Steel Product: Vehicle

Mould Diameter: 300-4000mm Length: 1000-4000mm Certification: ISO,SGS,CE

Voltage: 380V50HZ Warranty: 12months Name: concrete pipe mould

After-sales Service Provided:Engineers available to service machinery overseas

Packaging & Delivery

Packaging Details: in 40' top open container

Delivery Detail: Shipped in 30 days after payment

Introduction of Centrifugal Concrete Pipe machine:

The machine takes sands, stones and cement as raw materials to produce many kinds of reinforced concrete drainage pipe with the length of 1000-4000mm, internal diameter of 200-4000mm with the mouth shapes of flat, tongue and groove and socket and spigot. All mechanical indexes have meet the national standards. They have been used widely in deep well, municipal drainage, expressway and other water supply and sewerage works with higher level required. The production efficiency can reach 4-5 piece/hour.

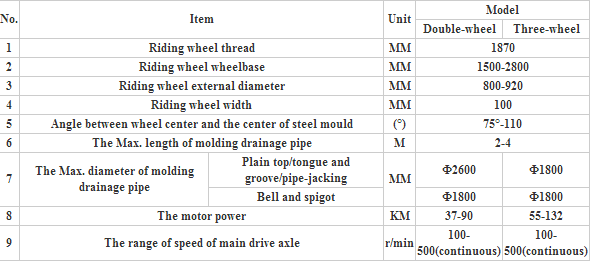

Technical of Centrifugal Type Pipe Making Machine:

The centrifugal machine is mainly used to manufacture the centrifugal equipments manufacturing the reinforced concrete drainpipes, driving the spinning of the drainpipe concrete pipe mold loaded with some concrete and reinforcing steel with a certain mixing ratio at different speeds, and the solid phase particles of concrete in steel mould will be centrifugal settling in the steel mould inner surface under centrifuge, meanwhile draining the excessive water, thus forming compacting concrete structure namely reinforcing concrete drainpipe. The machine mainly consists of riding wheels, shafts, bearing block, bearing, V-blet pulley, base and electromagnetic speed-controlling motor.

Features of Concrete Pipe Mould:

1.The adoption of integrated design is reinforced design of leakproof slurry, no rough edges on which the mouth of pipe joints, easy mold-opening.

2 .The friction rings in the molds are all made of 45 cast steel.

3 .The steel plate we use is produced by Laigang which is one of the four major steel mills, and its abrasion resistance will be guaranteed.

4 .The carbon-dioxide arc welding is applied into the all welding. The plasma cutting machine is used for cutting. Welding seam is smooth and nice, and the cutting seam is very exquisite. All above ensure the mold tough and durable and extend the service life greatly.

Related Equipment:

1. Concrete Mixers (rotary-drum-type, double-horizontal-shaft);

2. Concrete Batchers;

3. Concrete Mixing/Batching Plants (25-480m3/h, stationary, mobile, conventional-type, compact-type, simple-type, commercial-type);

4. Electiric pole making mould (8M-18M, round/square)

5.Well pipes and drain pipes making mould(2m,4m,8m)

6. Suspension cement pipe making machine

7. Centrifugal machine

8. Vertical extrusion molding machine

9. Reinforcement cage seam welder

10.Boiler

11.Feeding machine

Our Services:

1. Provide complete production line supporting machines with high performance and good quality;

2. Provide reasonable design of plant,office, warehouse etc and related drawings according to customers' requirements.

3. Provide all machines layout plan in production plant and responsible for the layout of machines.

4. Responsible for all Installation and commissioning of all machines as well as the workers production training.

5. Promise to supply required wearing parts of machines as per requirements of customers timely with favorable prices within 2 years.